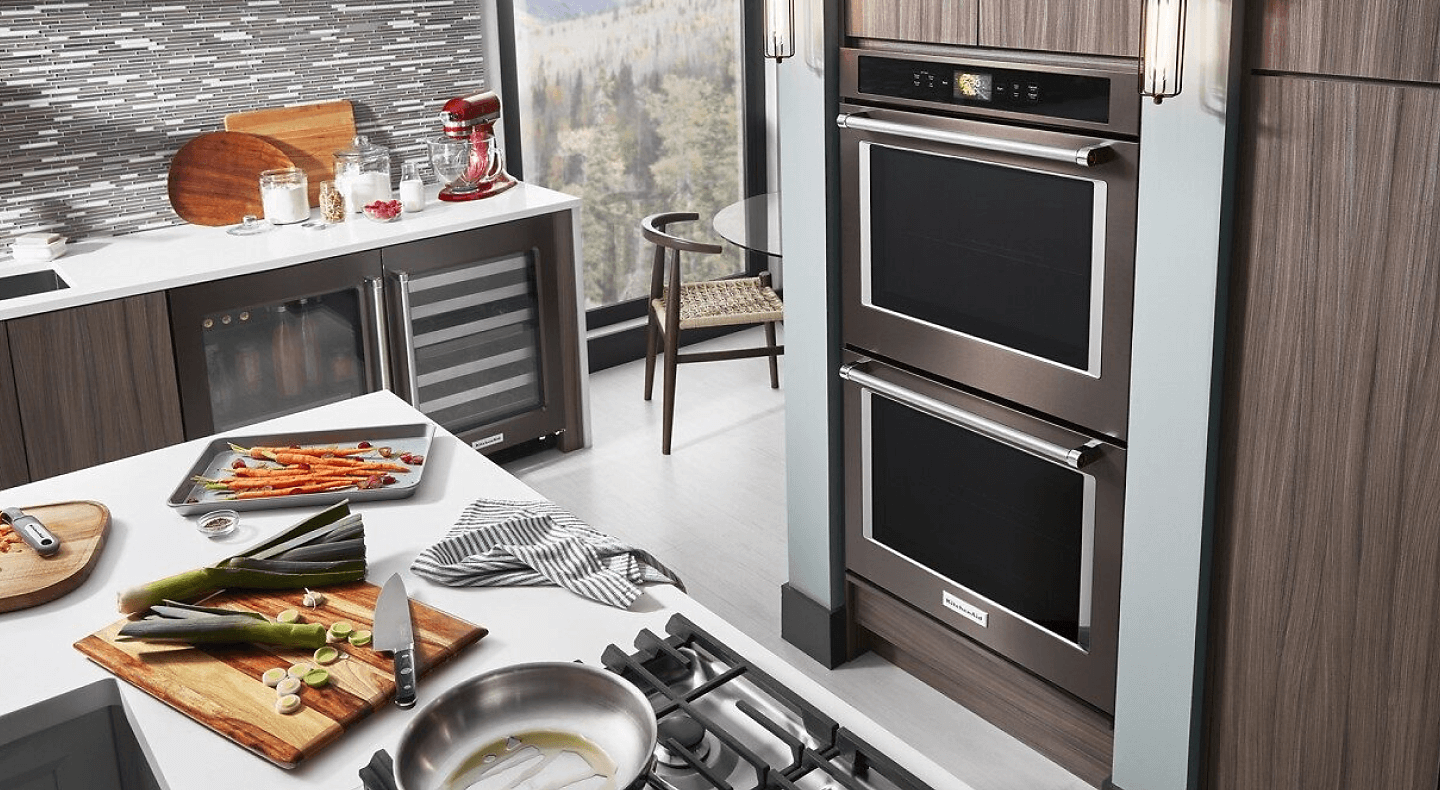

Applications in Food and Beverage Industry

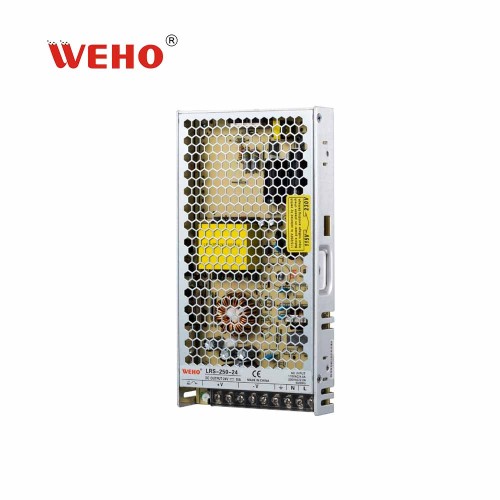

Switching power supplies offer high efficiency, compact size and flexibility, making them ideally suited to the diverse power requirements of the food and beverage industry. Their role extends to powering critical components that help improve the overall efficiency, safety and quality control of food processing and manufacturing processes.