Room Temperature

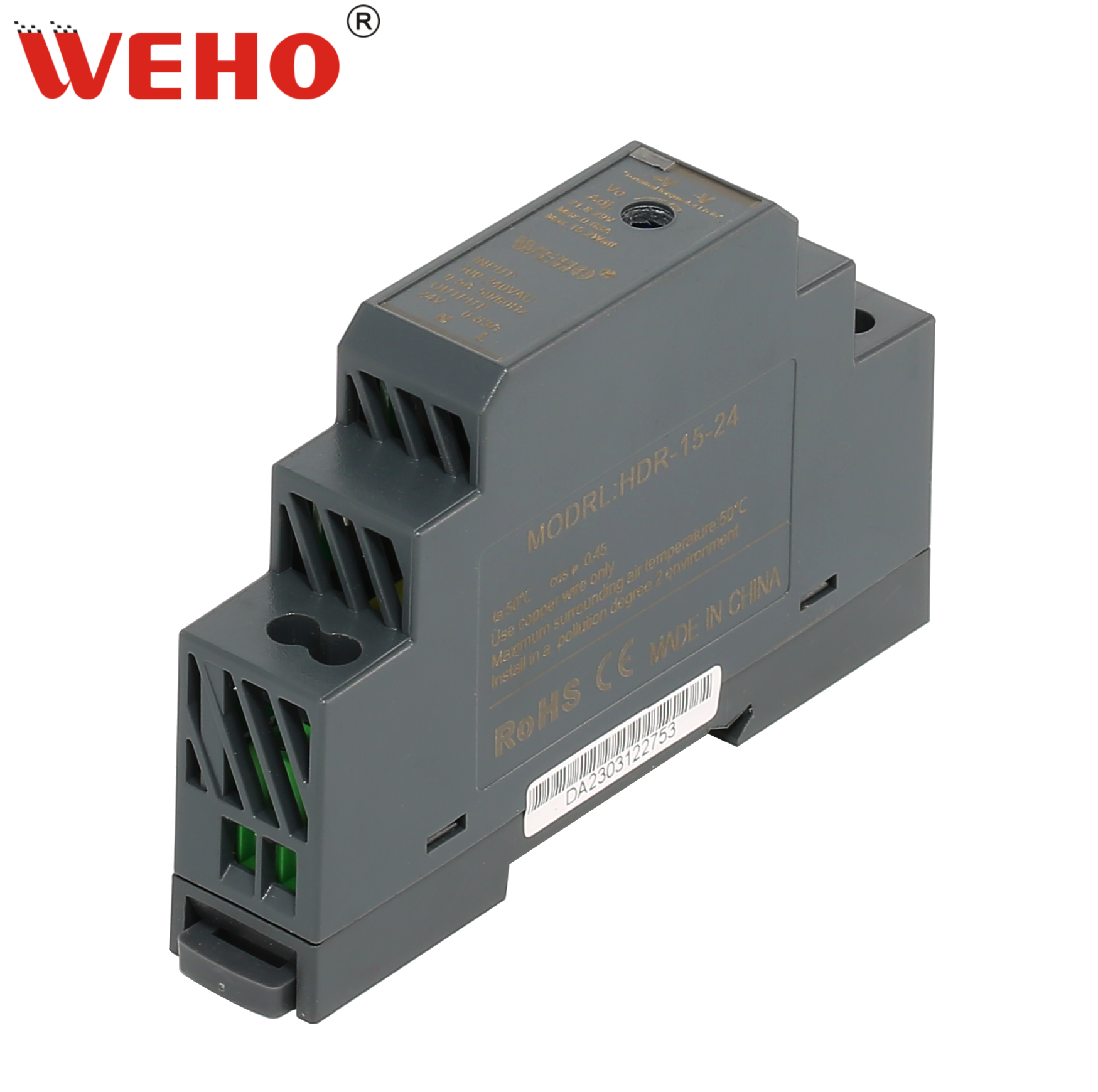

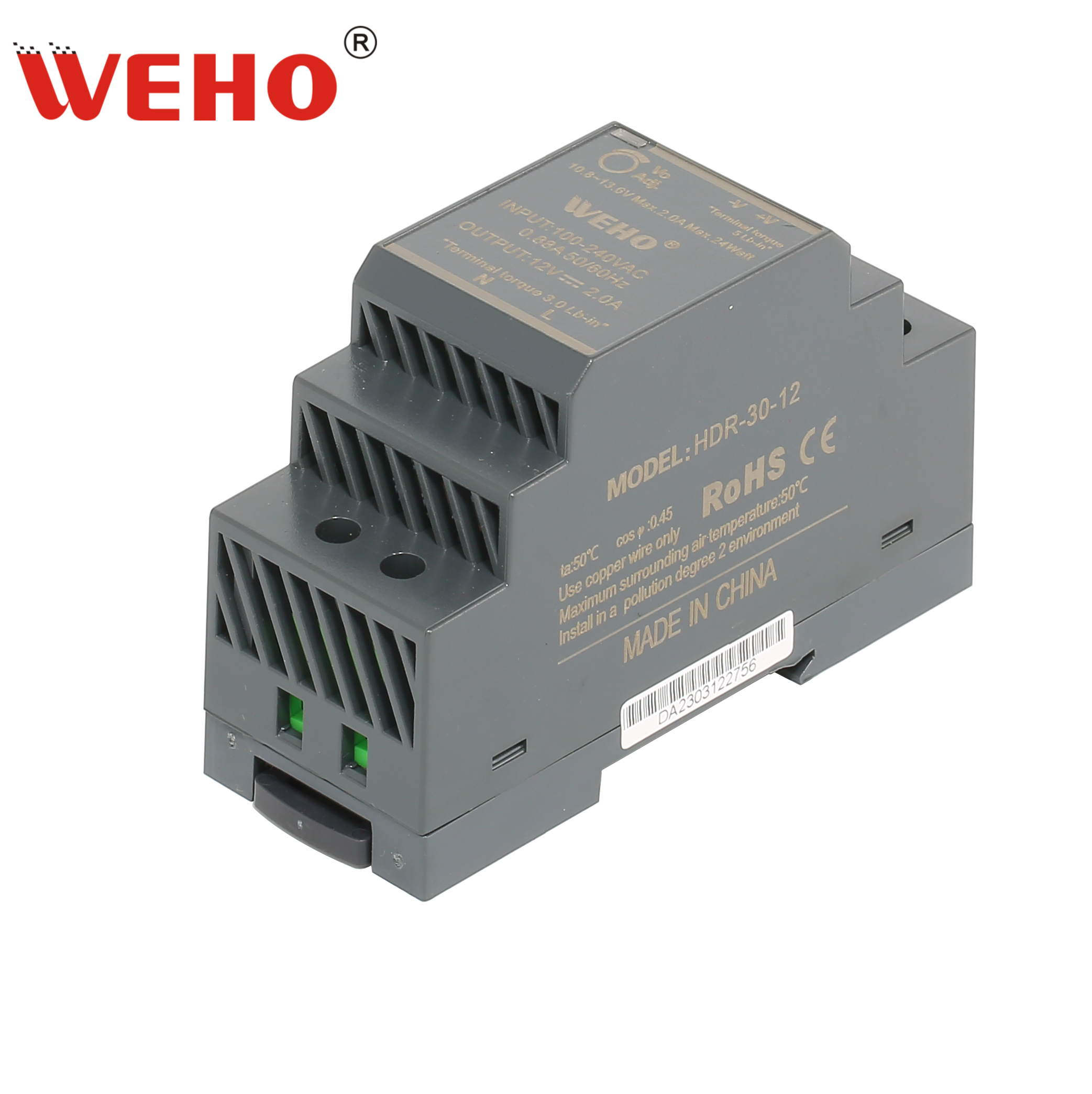

El calor es uno de los factores que más castiga a la electrónica, la zona en la que tengamos instalada la fuente de alimentación influye en su vida útil, generalmente se instalan en un lateral manteniendo la refrigeración y evitando que estén sometidas al calor generado por la cama caliente.

Generally, manufacturers of power supplies recommend a safety factor of 0.8. Or what is the same, that the working power does not exceed at any time 80% of the nominal value of the power supply, we recommend using a slightly greater factor so that our source lasts for years and years, even working at high temperatures.

0.6 is the Value We Recommend

In the previous calculation, we have obtained a working power of 205W, divided by 0.6, it gives us a power of 341.6W, so we will choose the power supply above 350w.